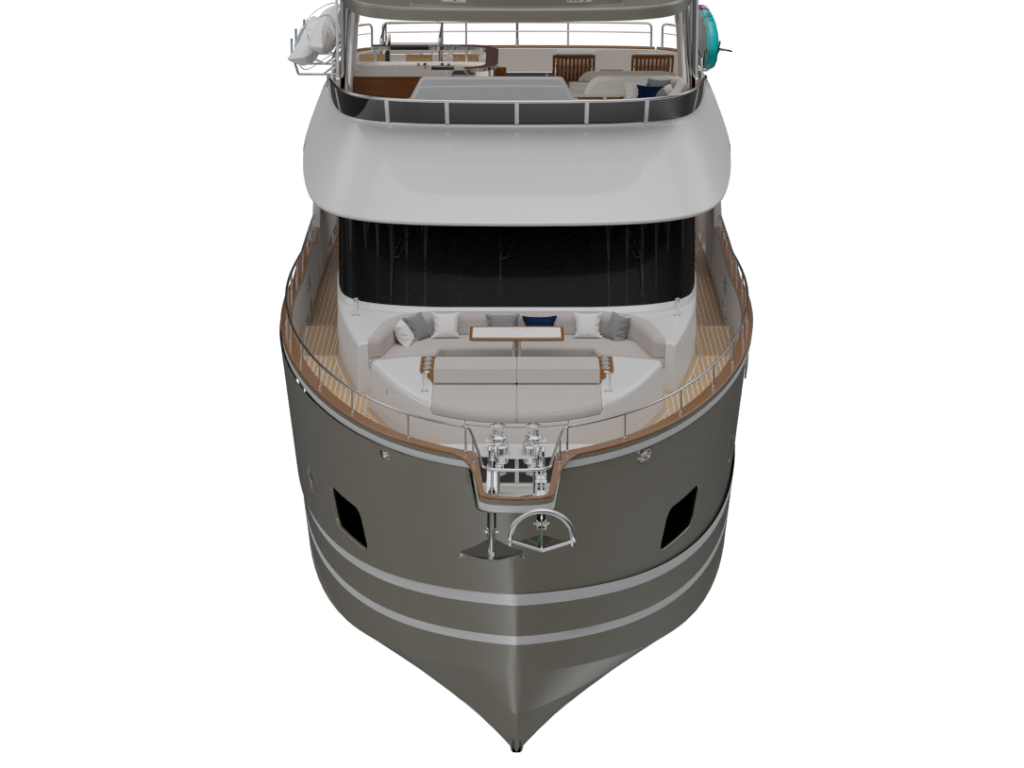

COR690 is an excellent yacht for long journeys. Its spacious interior provides functionality that is unique in this class. Its carefully designed semi-displacement hull has the best ecenomic properties at longitudinal travel speeds of 7-10kts. However, if you like to swim faster, the hull allows you to semi-glide at a speed of 20kts.

It is a condensation of space, versatility for all needs and all weather conditions.

If you want to sail fast or dignified by the shore – choose the right equipment and enjoy the enormous amount of space for the weekends.

You want to go far and economically? Choose the best-in-class John Deere diesels, redundant systems and sail around the world

The upturned bow prevents water from gathering in rough seas, large storm drains quickly drain excess water from the decks, positively influencing the stability in bad weather.

The possibilities of developing the interior are enormous. Three spacious cabins for 7 people. an additional convertible cabin with a small office for an additional two people. big dinghy on the flybridge, jetski on the swimming platform. Pantry, utility room with washing machine, dryer and ironing board. A crew cabin for two or a convertible 3rd. guest cabin. An additional unfolding sofa in the Pilot House with the possibility of covering

All this means that three generations will find a place for themselves while spending time by the water.

Thanks to the wide hull, as standard, there are two flybridge exits, one on the aft deck, the other directly from the Pilot House, perfectly connecting the communication on the yacht. There is also a place for a daily bathroom on the main deck. From the main deck you will get directly to the utility room and engine room. This solution ensures comfortable sailing on cold days and prevents the external parts of the yacht from entering these spaces.

As in each of our projects, maneuvering the yacht, its full engineering service has been developed so that it can be easily performed by the owner himself

Entry to the engine room is through full-size doors, ensuring safe operation in all conditions. The engine room itself is a perfectly laid out place with easy access.

Additional bottom elements, such as an extended keel or a cutting bulbous bow, are made on request

| PROPERTIES | [m] | [ft] |

| LOA Length overall | 21,5 | 70,6 |

| BOA Beam overall | 6,25 | 20,50 |

| LWL Loaded waterline length | 18,93 | 62,1 |

| BWL Beam at the waterline | 6,1 | 20,01 |

| T draft | 1,78 | 5,84 |

| DA draft air | 7,95 | 26,08 |

| D(T) Loaded displacment | 69,5 t | 153 221 lbs |

| CE APPROVAL CATEGORY | A OCEAN | |

| Maximum capacity | 12 people | |

| Hull type | Semi-displacment with ETE (Extended Trailing Edge) | |

| Hull Meterial | GRP | |

| Superstucuters / Deck | GRP | |

| Sleeping Cabin / Places | 5 for 9 People + 1 for 2 Crew | |

| Enigne Horse Power | from 2x750 to 2x1400 | |

| Speed | 7-23kts | |

| Averange range at 7kts | approx. 5050 NM 15%reserv | |

| POSITION | NAME | |

| Naval architect | Grzegorz Władziński | |

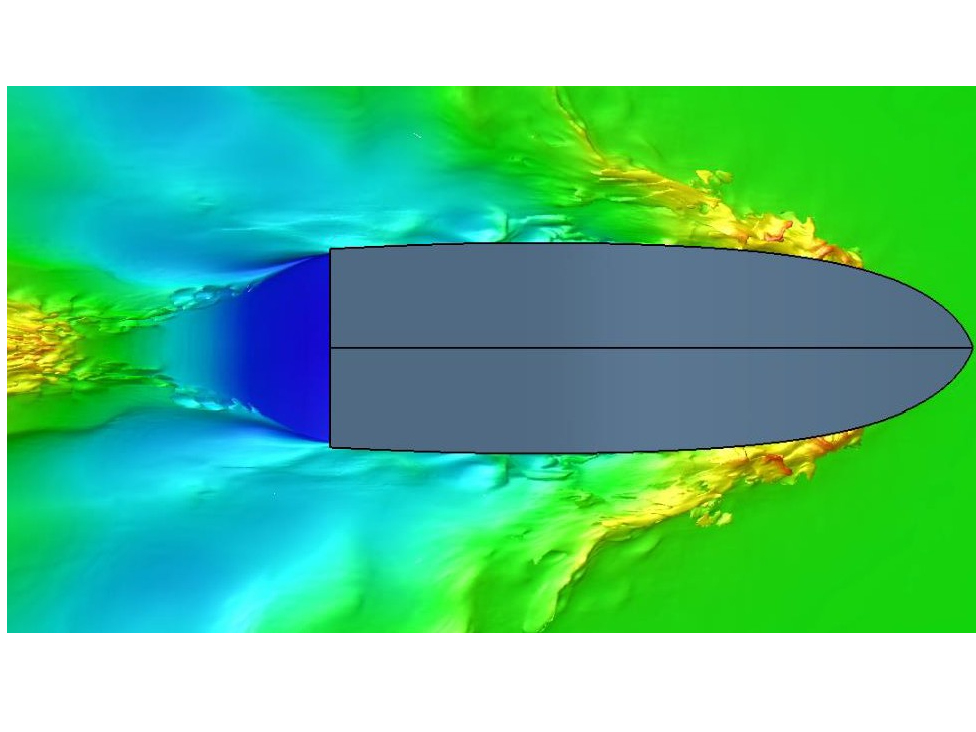

| Analysis CFD and improv. | Grzegorz Władziński | |

| Conception designer | CY Damian Dymecki | |

| Exterior designer | CY Paweł Pankowiak | |

| Interior designer | CY Paweł Pankowiak | |

| Construction designer | STRUCTeam LTD UK | |

| Builder | Cormornat Yachts Shipyard Gdańsk | |

| PROPERTIES | [L] | [GAL] |

| Diesel total | 9800 | 2588 |

| Potable water tank | 300 | 79 |

| Fresh water tank | 1800 | 501 |

| Gray water tank | 970 | 256 |

| Black water tank | 335 | 88 |

STANDARD VERSION SHORT SPECIFICATION

General Construction

Flybridge version with hardtop

Navigation mast

White or Ivory gel coat surface finishing

Swimming platform L=1800

Propulsion & Steering system

Twin SCANIA MARINE DI13 2x700Hp

ZF TRANSMISSION 550-1 SuperShift A driveline with 7 ° gear exit angle

Fuel tanks 2x2000l 528US gal = 4000L | 1056USgal

Regular fuel filtration

Fuel level indicator on filler plate on the starboard side

Bilge pump double – 6pcs, low and Hi-Level

Thruster Electric DC Bow – SIDE POWER PR200 9,76kW, Thrust up to 250kg

ZF CONTROL SYSTEM Advance SmartCommand with 2x 5200 Type

Magnus Master stabilization system

Electricity Level 1

KOHLER 12kW Power Generator

Inverter Victron Multi Plus 5000/24/230V

House/Hvac battery bank 500Ah//24V (10pcs. battery)

Two power sockets to on-shore connect 16A and 32A with two type 25m cable

Interior finishing

Modern flat panel style interior finished in two types

Premium quality fabrics

Galley equipment – Option 1 Bosch

Kitchenware:

Refrigerator / freezer Bosch Series 6 – KAG93AIEP

Dishwasher – Bosch Series 8 SMV8ZCX07E

Cooktop – Bosch Series 8 PXE601DC1E

Cooker hood – Bosch Series 4 DFT63AC50

Oven with microwave – Bosch Series 8 HMG636RS1

Coffee machine – Bosch Series 8 CTL636ES6 built-in

Wine fridge – Electrolux ERW1573AOA

Toaster – Bosch TAT7203

Electric kettle – Bosch TWK7403

Blender Bosch MMBH6P6B

Sink with battery: villeroy boch/duravit, grohe

Countertop – Granite Thick 30mm, 1 3/16″, Kashmir White class

Flooring – Ceramic tile or stone tile

Exterior finishing

Sofa with locker on the fore deck

On the aft deck, a sofas with a table and two chairs

In the foredeck there is a sofa, table, sitting area in front of the sofas,

Flybridge STANDARD

Large U shape Sofa with lockers

Large table. Cup holders.

Double captain chair with base. Textile materials from Sunbrella brand or similar.

FlyBridge: flat glass modern navigation panel with logo cormorant.

Deck floor finishing – gel coat anti non-surface , beige, gray, white to choose from.

WETBAR

Fiberglass cabinet wooden front, semi glossy finished.

Teak, SS, finished. Countertop Granite Kashmir white class,

sink with tap

Trash bin under sink

Drawers for dishes, inside from solid teak

Places for one 60cm wide device and one 40cm device, and 40cm cabinet

Cold & Hot Water, Gray water drain

230V Sockets 4x Berker

Grill KENYON, Icemaker Isotherm IceDrink Clear

Deck floor finished – Anti Skid surface, white,gray,beige color chosen from.

AIR CONDITION, Cooling and heating

Webasto Chilled Inverter Unit 8500-77000Btu/j | 2,5-22,6kW

6x 18,000Btu/h Air handler unit

Primary Water boiler 300L | 79Usgal

Secondary Water boiler 60L | 15Usgal (only for master stateroom)

Pipeline for cold&hot water, gray, black water, VIEGA pipelines system

All sanitary tank made HDPE material, Tek-Tanks, UK

Watermaker – PARKER Aqua Pro mini 27l/h – 7USgal

Fire protection – 2x Seafire

GARMIN NAVIGATION & COMMUNICATION LEVEL 1 – Coastal Pilot config.

MULTIFUNCTION DISPLAY & NAVIGATION

GPSMAP 8412 MFD 16″ 3pcs in extra wide, One frame less display 115cm x 19,5cm – in the Pilot House

GPSMAP 8416 MFD 16″ 2pcs in the Fly bridge

SONAR Panoptix LiveScope

GPS ANTENNA 24XD

PRIMARY AUTOPILOT REACTOR 40

SENSORS SAIL PACK 52 GNX (wind speed, wind direction, outside temp, watter temp.)

RADAR GMR FANTOM 18

CAMERA IP GC 200 in the engine Room

CAMERA IP GC 200 view stern direction

Communication:

Primary VHF – VHF 215i Pilot House + Full function handset on the Flybridge

Secondary VHF – VHF 215i Pilot House + Full function handset on the Flybridge

Transponder AIS 800 TRANSCEIVER CLASS B

Antenna GA™ 38 GPS/GLONASS

inReach Mini Marine Bundle – Iridium satellite communicator

Fusion stereo system 12 speakers & PANASONIC TV 55”+24”+24”

For yachts configured as Long Range Cruiser, an additional mechanical driven pump is installed directly from the main engine. As the hull has a sandwich structure, it can be assumed that during a collision, e.g. with a shipping container, the plating will become unsealed but not torn enough to create a significant hole. In line with this, an additional pump will constantly pump water out of that section.

More information is contained in the individual specification ranges on the following sheets

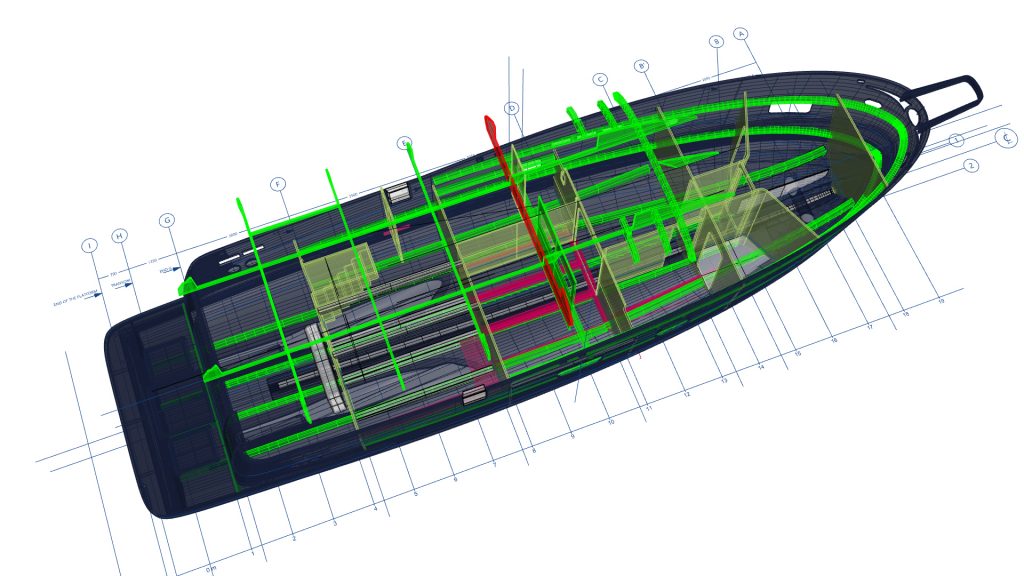

Thanks to the excellent experience of the design office Structeam from the UK, the structure has been designed in a very thoughtful way. The weighted months are made of a very large amount of reinforcements and a significant thickness of the laminate. However, in places where the structure does not carry loads, it is lighter. Such a method is typical of sophisticated methods of designing advanced yachts and it boldly displaces methods in which heavy structures are installed without much justification. Instead of weight, we use sophisticated materials and infusion lamination. Weight is the basic parameter influencing the economy of swimming. Thus, this aspect contributes to the definition of our units as ecological.

Construction type: GRP – all parts manufactured in Vacuum Infusion Process

Primary materials :

Finishing laminate surfaces

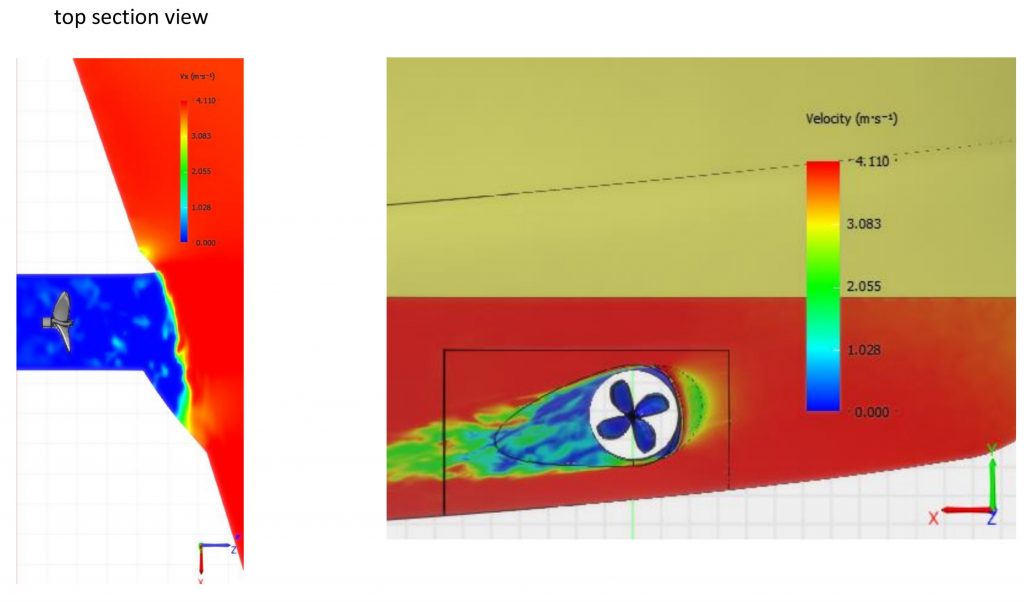

All the hulls we use have been designed directly for us by the office of engineer Grzegorz Władziński. In response to the high demands, hulls were created that combine the following features.

We do not use traditional pressure bulbous bows as they are only suitable for one speed. Instead, we use a more useful solution. Cutting bow that increases efficiency with speed.

Checking the correctness of the arrangement of storm drains. Pre-calculated openings based on the guidelines of classification societies. We check many CFD analyzes.

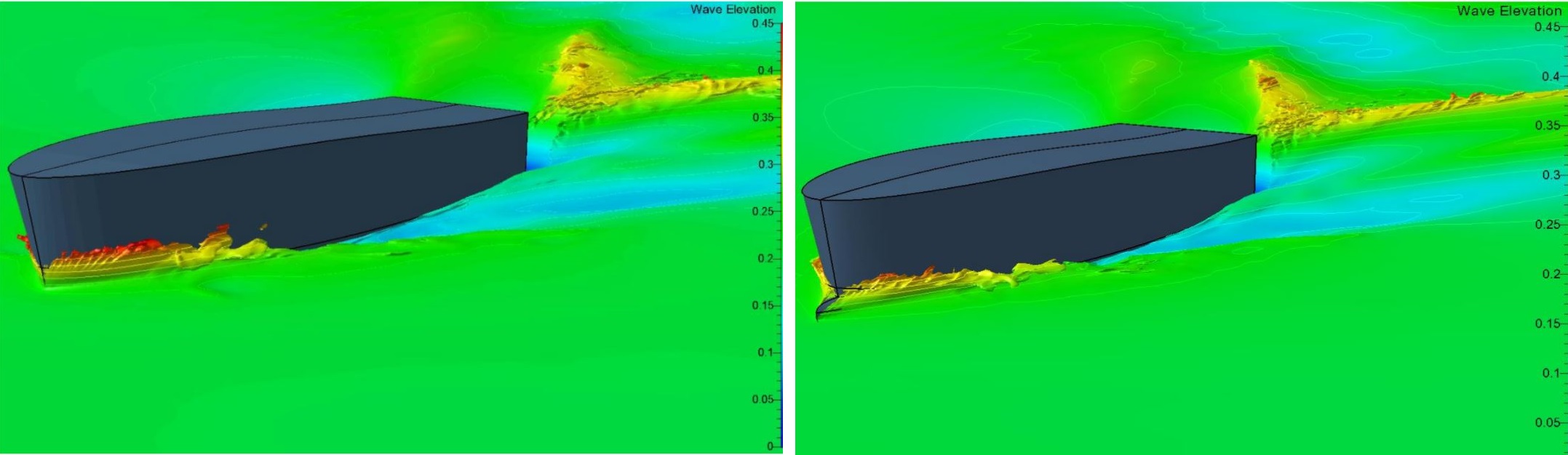

We have completed complex CFD analyzes confirming the high seaworthiness of our hull for the 690 and 780 models.

We used a yacht loaded with 3/4 of its capacity for the analysis. although it is not visible on the model, the input data includes the weight of 750 kg on the flydeck as a dinghy.

The versions with an extended keel but without additional ballasting were adopted. The stabilizing devices are not involved in these tests. We want the analyzes to take place with the worst scenarios.

The wave taken in the analysis has a high frequency, which is particularly dangerous at sea.

In addition to research at sea. We performed an examination of the straightening arm.

Righting lever force test for heel to port 90 °

One of the worst situations.

This is particularly difficult due to the enormous amount of water taking up on the decks. Please pay attention to the work of the water drains from the decks. How important is their size and location.

As the effectiveness of the rotors is already very noticeable at low speeds, the risk of seasickness is minimal.

The innovative system drive ensures far fewer moving parts, resulting in reduced noise level. The MagnusMaster is simply very quiet.

The control of the system is user-friendly and can be integrated into the onboard system. Operation is simple via an easy-to-read full-colour touch screen.

The MagnusMaster has been developed for your convenience.

Roll damping with the MagnusMaster is much more effective when the yacht is at speeds of 3 to 12 knots.

The MagnusMaster is fully electric and directly driven, eliminating the need for a fan belt. Maintenance-free bearings are used around the shafts. DMS has kept the technology as simple as possible, so that hydraulics, pumps, cylinders and pressure pipes are not necessary. This makes leaks and other hydraulic-related malfunctions, as well as unpleasant noise, a thing of the past.

Your MagnusMaster stabilisers do their job worry-free, safely, quietly and very effectively.

The entire system is electrically retractable, preventing damage in shallow water. When retracted, the rotors remain within the turbulent boundary layer of the hull and resistance is therefore negligible, producing a favourable effect on fuel consumption. When retracted, they are almost impossible to damage during transport.

Because the rotors do not have any steering effect, the positioning — unlike with traditional fins — can be freely determined and a suitable place can always be found to install the very shallow and compact electric motor. Loss of space is therefore kept to a minimum and major renovations in the engine room are not necessary.

At DMS, the safety of people on board is key. That is why the rotors are automatically retracted when the vessel’s engine is put into neutral or the drive drops out. This prevents damage during maneuvering and mooring at a quay, lock, harbour or around other vessels and safety is guaranteed.

The operation of the DMS ARG is problem-free. Zero speed stability is guaranteed for fast yachts and slow sailing yachts and is suitable for all hull shapes. In addition, the operation is much quieter than other gyros on the market and gives optimal results faster. Another advantage is the considerably shorter ‘read-out time’. Due to the larger gimbal angle – 180 degrees instead of 120 degrees – the DMS ARG responds better to higher waves. In other words, more damping of roll movements.

The fundamental concept and construction are much more durable due to the reduced design complexity compared to other providers in the gyro market. Smart thinking results in:

No penetrations through the hull; only a solid foundation needed

No need for water for cooling or a hydraulic system to operate fins

An exhaust fan only preferable in a confined space

Maintaining a vacuum is not necessary

Reduced complexity means fewer parts for maintenance or breakage

Air cooling has long since proven itself to be completely problem-free. The ARG has been running for years in various engine rooms of large commercial ships. It gets much hotter there than in any engine room on a yacht

Significantly longer service intervals that are easier to check thanks to read-outs

The ARG originates from the development of gyros for a space station. That high quality is incorporated in the ARG placed in your yachT

Ultimately, of course, it is about results. Comparative tests have shown that:

The DMS ARG is operationally faster than the alternatives available from other suppliers

Using a larger gimbal swing angle of 180 degrees guarantees stabilisation for longer in higher waves. This makes the torque output the highest in the market

The focus on durability, and therefore to keep maintenance requirements as low as possible, was already addressed during the design phase. That makes the shipyards’ job much easier. What else can you expect?

Installation is simple. There are no hull penetrations, only a solid foundation is needed

The relatively simple installation makes retrofitting possible

There is no electrical control unit resulting in far fewer malfunctions and a high level of safety

The bearings of the DMS ARG last up to 5x longer than those from competing brands

No water cooling required, meaning maintenance intervals are much longer

Simplicity was the starting point in the design. That has resulted not only in excellent durability, but also much lower production costs for the DMS ARG. The price/performance is therefore the best in the market. In short: the more torque, the greater the price advantage compared to other providers in the market. Up to 40% cheaper!

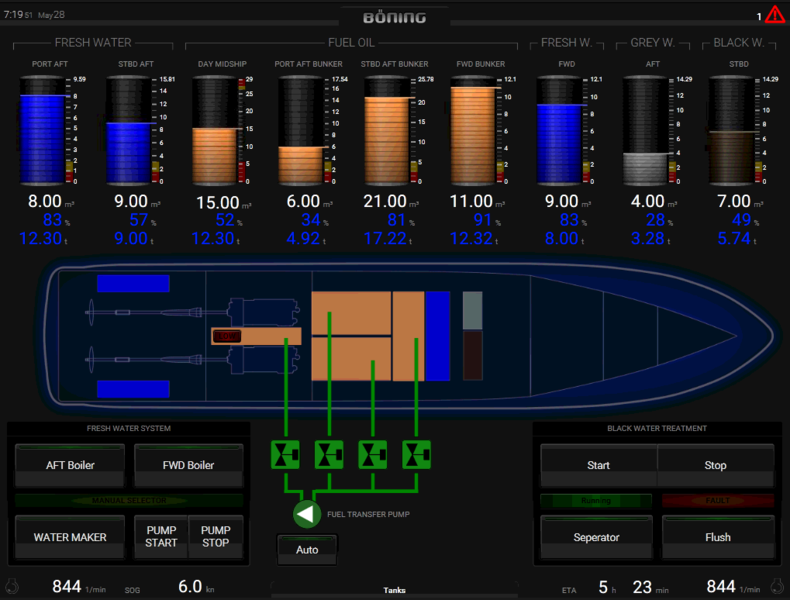

Each CORMORANT has a hard-wire automation system. It is a panel with aesthetic buttons and controls. Its operation is the simplest possible. Starting a given system is done by pressing a button – and that’s it.

This solution allows the vast majority of devices to be connected with ordinary contactors. When the need arises, everyone will make repairs.

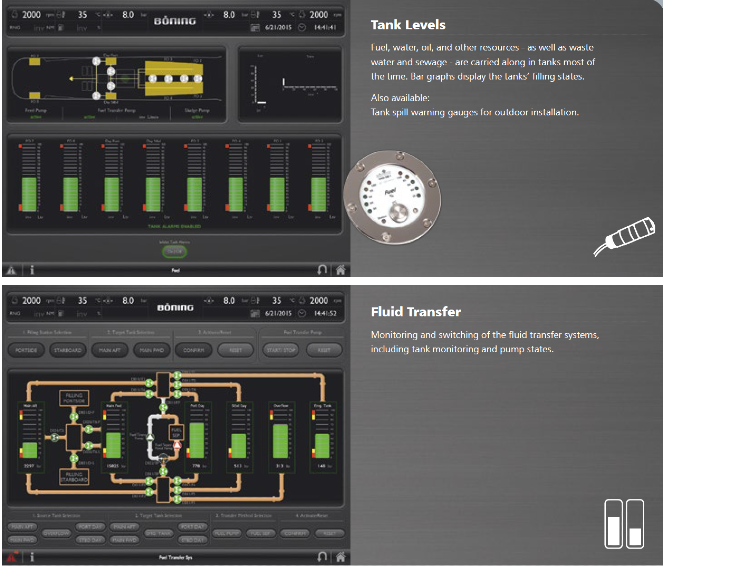

Moreover, for monitoring drive systems and generators. We assemble a Hi-End BOENING automation system. It is the highest possible quality electronic system made in Germany.

The system is expanded depending on the selected other equipment components.

The BOENING system watches over all the yacht’s systems and displays them on its own screen or as a page on the MFD.

The levels in the tanks are also displayed in this system.

The system allows for enormous expansion possibilities according to customer wishes

Each CORMORANT has a BOENING ignition with an immobilizer.

Switch cabinets

First of all, it should be noted that regardless of the adopted configuration, solutions and materials are of the highest quality to ensure the highest level of safety and many years of trouble-free operation

ELECTRICAL SYSTEM

Each of the CORMORANTS has two basic power systems.

LEVEL 1 – this is the range of devices without redundancy, corresponding to the coastal rib. Built on the basis of one KOHLER 12kW current generator. Large 6400W 24VDC / 230VAC Inverter and 500Ah Battery Bank common to all on-board devices.

One shore connection socket at the stern.

Starting aid for CYRIX engines / generators

LEVEL 2 – is a range of devices dedicated to units in the LRC configuration, and for those who expect higher comfort / security.

The scope has redundant systems. Split port and starboard layout. Switchable.

Two power generators (18kW large and 12kW small) associated for parallel operation, able to synchronize their work. This configuration allows the large generator to be turned off at night and only a small one will turn on when needed.

Two 6400W 24VDC / 230VAC inverters work in this system.

Two large 720Ah battery banks each

Additional 2 skylla chargers with universal input. They act as a backup for inverters and allow you to connect a 120V power supply

Two additional alternators mounted on 175A engines each

Two isolation transformers for shore power protection.

Two Glendinning cable dispensers at the stern.

Two nests in the stern + two nests in the bow.

Starting aid for CYRIX engines / generators

Generators can be increased on customer’s request in each system.

You can change the type of batteries in each system. from AGM to LiFePO4 (Lithium Iron Phosphate Battery)

In each system, upon the customer’s request, other sockets, switches and power architecture can be used.

Each power supply system is easy to use and the switchboards are intuitive.

Each power supply system has a separate battery bank to maintain the radio function and a single plotter with a GPS antenna for several dozen hours in the event of a total failure.

This bank is located above the main deck.

Each CORMORANT has six large earthing plates located in such a way that the loads are always discharged.

Basic navigation solutions are divided into two levels.

Each CORMORANT is equipped with the LEVEL 1 navigation kit

NAVIGATION LEVEL 1

MULTIFUNCTION DISPLAY & NAVIGATION

GPSMAP 8412 MFD 12″ 4pcs in extra wide, One frame less display 104cm x 14,5cm – in the Pilot House

GPSMAP 8416 MFD 16″ 2pcs in the Fly bridge

SONAR Panoptix LiveScope

GPS ANTENNA 24XD

PRIMARY AUTOPILOT REACTOR 40

SENSORS SAIL PACK 52 GNX (wind speed, wind direction, outside temp, water temp.)

RADAR GMR FANTOM 18

CAMERA IP GC 200 in the engine Room

CAMERA IP GC 200 view stern direction

Communication:

Primary VHF – VHF 215i Pilot House + Full function handset on the Flybridge

Secondary VHF – VHF 215i Pilot House + Full function handset on the Flybridge

Transponder AIS 800 TRANSCEIVER CLASS B

Antena GA™ 38 GPS/GLONASS

inReach Mini Marine Bundle – Iridium satellite communicator

Basic antennas set included:

One VHF Shakespeare 5230 Galaxy

One AIS Shakespeare 6396-AIS-R Phase III

finished in superstructure colour

For LRC configurations, a Level 2 navigation system is fitted upon customer request

NAVIGATION LEVEL 2

MULTIFUNCTION DISPLAY & NAVIGATION

GPSMAP 8422 MFD 24″ 2pcs in the Pilot House

GPSMAP 8424 MFD 24″ 1pcs in the Pilot House (central position)

GPSMAP 8416 MFD 16″ 2pcs in the Fly bridge

SONAR Panoptix LiveScope

GPS ANTENNA 24XD

PRIMARY AUTOPILOT REACTOR 40

SENSORS SAIL PACK 52 GNX (wind speed, wind direction, outside temp, water temp.)

RADAR GMR FANTOM 18

RADAR GMR 1226 xHD2 open array antenna

CAMERA IP GC 200 in the engine Room

CAMERA IP GC 200 view stern direction

Communication:

LRC Transceiver package based on ICOM include:

Primary Radio Station VHF – Icom M605EURO Output Power: 1W/25W in the Pilot House + Flybridge stand alone panel

Secondary Radio Station VHF – Icom M605EURO Output Power: 1W/25W in the Pilot House + Flybridge stand alone panel

Icom M605Euro – Third stations Total Thee (3):

1.Engine Room Icom COMMANDMIC HM-229B + cables OPC-2384, 2.Crew Cabin, 3. Master Cabin

Radio Station HF/MF SSB – Icom M803 SSB Output Power:150W Frequencies 0.5-29.99Mhz

Radio Station SSB – The AT-140 automatic antenna tuner from ICOM M803 [is suitable for 1.6 to 30 MHz. Ideal for whip antennas, backstays etc. For 100 watts continuous power or 150 watts PEP]

Transponder AIS 800 TRANSCEIVER CLASS B

Antena GA™ 38 GPS/GLONASS

SATELLITE COMPASS MSC 10

inReach Mini Marine Bundle – Iridium satellite communicator

LEVEL 2 antennas package included:

One VHF Shakespeare 5230 Galaxy

One VHF Shakespeare 5309-R Galaxy VHF 23’ (7m) VHF Marine Band 9dB

One HF/MF Shakespeare 5310-R Galaxy SSB 23’ (7m) Full-Length Conductors

One AIS – Shakespeare 5225-XT-AIS Galaxy AIS/VHF Antenna 8′ (2.4m) 6dB Gain

One HDTV Shakespeare 3019 SeaWatch® Seawatch ® Marine TV Antenna (19″ Diameter)

One Shakespeare 5235-XT Galaxy AM/FM Antenna 8’ (2.4m) AM/FM Entertainment Band

One Shakespeare 5239 Galaxy 9.25″(0.23m) World Band Cellular Antenna

One Shakespeare – WiFi receiver in Marinas 5248 Galaxy Wi-Fi Antenna 24″(61cm) Gain:8dB

finished in superstructure colour

At the customer’s request, a second autopilot system with a KOBELT pump is installed

Thermal camera is also available on request in level 1.

There are a number of options for extending the navigation systems at the customer’s request.

CORMORANTS can offer navigation MFD systems from three companies: GARMIN, RAYMARINE, FURUNO. Other companies are available too.

DESIGN

When designing our yachts, the main emphasis was placed on the function and presence of the yacht owner as the capitan. Our yachts, despite their large size, can be driven yourself if you want. We will adjust the equipment so that it is possible without stressful situations.

You can also hire the crew if you want. Our project is prepared for this.

In fact, there are no contraindications for which a full-blooded travel trawler could not be nice, comfortable, with places for sunbathing and fishing from a spacious swimming platform.

So we did it.

Our designs are original because they perfectly combine the travel possibilities of yachts with a calm design. We have not deprived our yachts of elegance to look like an old fishing boat. At the same time, they are not targeted at one group of customers.

Our yachts are liked by both great travelers as well as those who begin their adventure with yachting and who want to sail along the coast.

Both of them share the same feature, the willingness to sail a yacht that is well-designed and perfectly made. A yacht where everyone can contribute during construction.

Our yachts combine all the best features of old Taiwan or US trawlers, but do not have any of their disadvantages

All our yachts will be built in our design office. The entire team has a direct impact on the projects. Both architects, technologists and system engineers.

HIGHLIGHTS

Below we present charts on the basis of which you can get an idea of the range of our yachts. Please note that these values apply to yachts with standard equipment. additional tons in the form of optional equipment or the amount of fuel in additional tanks will affect the power demand and, consequently, the reduction of the range.

Each CORMORANT can be configured with additional fuel tanks.

First of all, it should be noted that regardless of the adopted configuration, solutions and materials are of the highest quality to ensure the highest level of safety and many years of trouble-free operation

See description in the SAFETY FIRST tab

Fresh water distribution.

Gray water, toilets and waste water management

Emptying in the port. Could be pumping out the black water tank. While gray water is pumped into the black water tank. This solution helps to clean the black water tank. In addition, next to the sewage suction point, there is a rinsing valve, through which we can supply fresh port water, for cleaning the tank. The valves are located at the PilotHouse in degrees on the half deck starboard

Emptying in the sea. When the rules and common sense allow it. The gray water tanks are emptied directly into the sea using a sewage pump. The same has been solved for emptying black water.

WINDSHIELD WASHING SYSTEM

DECK WASHING SYSTEM & ANCHOR WASHING SYSTEM

AIR CONDITION

EXTENSIVE HEATING SYSTEM

GENERAL VENTILATION SYSTEM

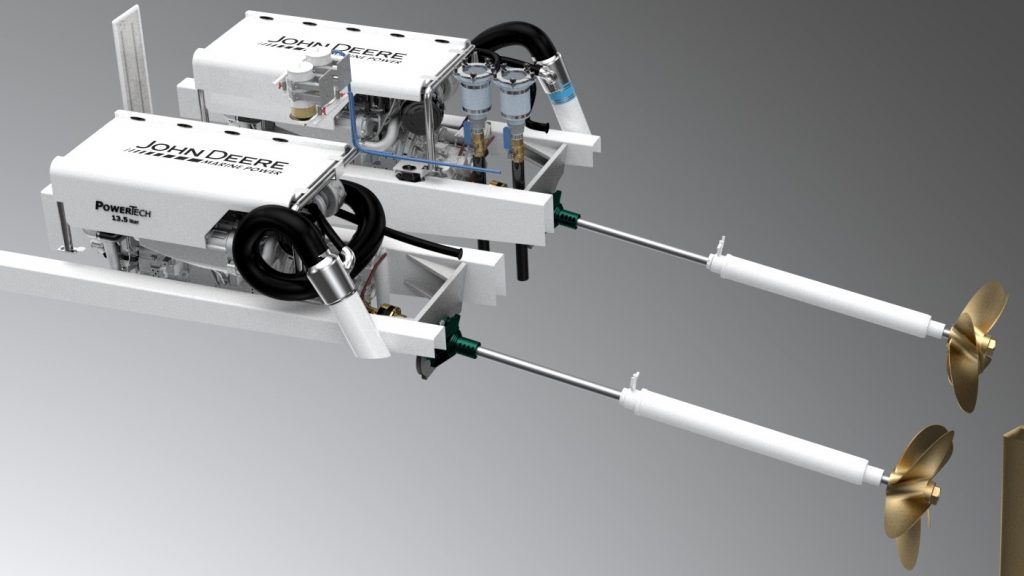

When defining customer needs, we assumed a double drive system for a much cheaper one with one large engine.

Using different engines for different purposes, we assumed that the drive transmission would always be the same. A simple and proven angular output from the transmission, which is integrated with the engine.

This guarantees the lowest number of parts and excellent service access. The simplicity of the design that can be handled by a mechanic anywhere in the world.

On request, in order to reduce natural vibrations from the propeller and vibrations from the engine, the assembly of the thrust transfer system from the propeller to the thrust bearing mounted on the technical bulkhead. In this solution, the motor and gearbox have extremely flexible vibro-shock absorbers ensuring excellent comfort.

We can assemble the engine of any manufacturer at the customer’s request. Why do we propose these brands

SCANIA engines are extremely economical and provide high torques from the lowest revs.

We can order an engine with slightly worse parameters with a charge air cooler with cooled water from the engine cycle. This solution prevents the cooling channels from clogging up when cooled with seawater. The entire structure is designed in a way that guarantees work in the worst conditions. They have a very good power to price ratio. They come in 4 and 6 cylinder in-line configurations.

The 6135 engines are exceptionally well balanced, providing excellent working comfort.

While it’s never good for an engine, these engines resist service neglect like no other.

They are of particular importance to those who want to sail around the world without worrying about accessing parts. As is commonly known. This manufacturer’s agricultural machinery is recognized all over the world. Therefore, access to parts is available in every agricultural store in the world.

We use two types of engine and transmission suspensions.

We make mounts for suspensions according to our designs, they allow for easy replacement of worn vibrozillotors. They have multidirectional regulation. This solution allows the use of vibration isolators other than the originally installed, without the need to replace the mount. This applies to cases of damage in the farthest corners of the world.

The engine and transmission are mounted on extremely rigid stringers built over the structural stringers. The stringers are made of solid laminate reinforced with multi-directional glass fiber mats, and strapping cords. In addition, the upper part of these foundations is forged with a stainless sheet with a thickness of 8mm – 5/16 „

SHIPYARD LOCATION

Twarda 6A

80-871 Gdańsk

CONTACT

office@cormorantyachts.com

All rights reserved. © 2021, Cormorant Yachts

design: Hajduk Studio