16th of April 2022

Easter greetings from the CormorantYachts Team.

10th of February 2022

Last week, we completed complex CFD analyzes confirming the high seaworthiness of our hull for the 690 and 780 models.

We used a yacht loaded with 3/4 of its capacity for the analysis. although it is not visible on the model, the input data includes the weight of 750 kg on the flydeck as a dinghy.

The versions with an extended keel but without additional ballasting were adopted. The stabilizing devices are not involved in these tests. We want the analyzes to take place with the worst scenarios.

The wave taken in the analysis has a high frequency, which is particularly dangerous at sea.

In addition to research at sea. We performed an examination of the straightening arm.

Below is the result of the analysis from the form of animation.

21st of January 2022

As the effectiveness of the rotors is already very noticeable at low speeds, the risk of seasickness is minimal.

The innovative system drive ensures far fewer moving parts, resulting in reduced noise level. The MagnusMaster is simply very quiet.

The control of the system is user-friendly and can be integrated into the onboard system. Operation is simple via an easy-to-read full-colour touch screen.

The MagnusMaster has been developed for your convenience.

Roll damping with the MagnusMaster is much more effective when the yacht is at speeds of 3 to 12 knots.

The MagnusMaster is fully electric and directly driven, eliminating the need for a fan belt. Maintenance-free bearings are used around the shafts. DMS has kept the technology as simple as possible, so that hydraulics, pumps, cylinders and pressure pipes are not necessary. This makes leaks and other hydraulic-related malfunctions, as well as unpleasant noise, a thing of the past.

Your MagnusMaster stabilisers do their job worry-free, safely, quietly and very effectively.

The entire system is electrically retractable, preventing damage in shallow water. When retracted, the rotors remain within the turbulent boundary layer of the hull and resistance is therefore negligible, producing a favourable effect on fuel consumption. When retracted, they are almost impossible to damage during transport.

Because the rotors do not have any steering effect, the positioning — unlike with traditional fins — can be freely determined and a suitable place can always be found to install the very shallow and compact electric motor. Loss of space is therefore kept to a minimum and major renovations in the engine room are not necessary.

At DMS, the safety of people on board is key. That is why the rotors are automatically retracted when the vessel’s engine is put into neutral or the drive drops out. This prevents damage during maneuvering and mooring at a quay, lock, harbour or around other vessels and safety is guaranteed.

The operation of the DMS ARG is problem-free. Zero speed stability is guaranteed for fast yachts and slow sailing yachts and is suitable for all hull shapes. In addition, the operation is much quieter than other gyros on the market and gives optimal results faster. Another advantage is the considerably shorter ‘read-out time’. Due to the larger gimbal angle – 180 degrees instead of 120 degrees – the DMS ARG responds better to higher waves. In other words, more damping of roll movements.

The fundamental concept and construction are much more durable due to the reduced design complexity compared to other providers in the gyro market. Smart thinking results in:

No penetrations through the hull; only a solid foundation needed

No need for water for cooling or a hydraulic system to operate fins

An exhaust fan only preferable in a confined space

Maintaining a vacuum is not necessary

Reduced complexity means fewer parts for maintenance or breakage

Air cooling has long since proven itself to be completely problem-free. The ARG has been running for years in various engine rooms of large commercial ships. It gets much hotter there than in any engine room on a yacht

Significantly longer service intervals that are easier to check thanks to read-outs

The ARG originates from the development of gyros for a space station. That high quality is incorporated in the ARG placed in your yachT

Ultimately, of course, it is about results. Comparative tests have shown that:

The DMS ARG is operationally faster than the alternatives available from other suppliers

Using a larger gimbal swing angle of 180 degrees guarantees stabilisation for longer in higher waves. This makes the torque output the highest in the market

The focus on durability, and therefore to keep maintenance requirements as low as possible, was already addressed during the design phase. That makes the shipyards’ job much easier. What else can you expect?

Installation is simple. There are no hull penetrations, only a solid foundation is needed

The relatively simple installation makes retrofitting possible

There is no electrical control unit resulting in far fewer malfunctions and a high level of safety

The bearings of the DMS ARG last up to 5x longer than those from competing brands

No water cooling required, meaning maintenance intervals are much longer

Simplicity was the starting point in the design. That has resulted not only in excellent durability, but also much lower production costs for the DMS ARG. The price/performance is therefore the best in the market. In short: the more torque, the greater the price advantage compared to other providers in the market. Up to 40% cheaper!

24th of December 2021

13th of December 2021

We are after Friday start-up of the engines that will be installed in the COR555 / 690 model.

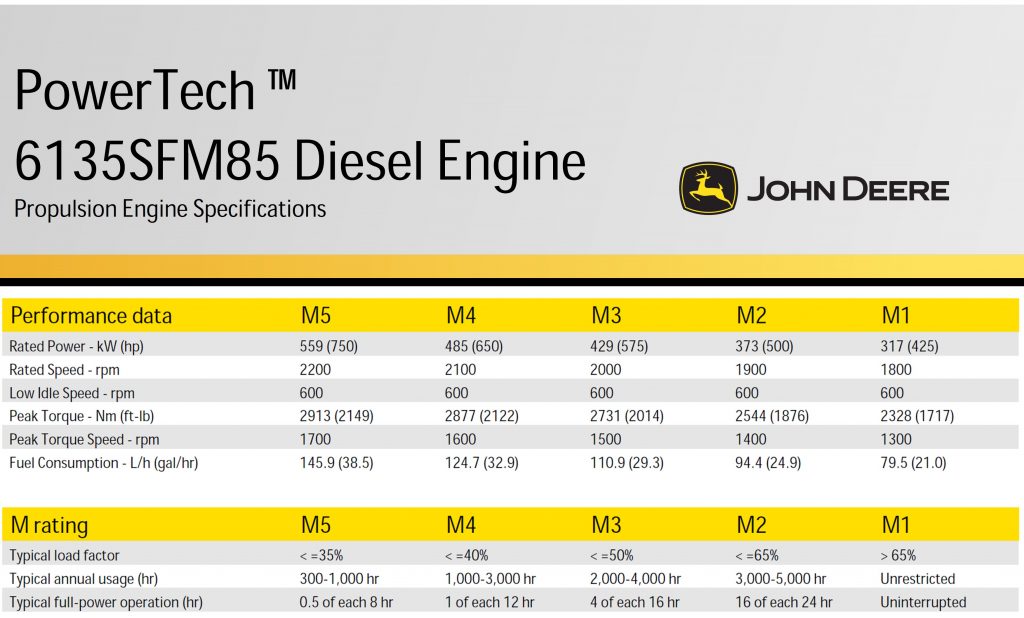

We started and checked the work of JOHN DEERE 6135SFM85 M2 engines, they are exceptionally balanced engines. The client decided on because they combine many advantages. They are very durable, they are made with a large material redundancy. They are indeed heavy. The engines will prove themselves in all conditions. Their service is possible all over the world at an increasing price.

In this vessel, they will run at 7-10kts, sometimes a little faster. Thus, our client will have a power reserve.

The engines are rated John Deere M2, as you can read from the cards below it is a hard work rating.

We always check the engines a few weeks before assembly in the hull.

In the videos you can hear how the engines work at 900RPM. We expect this to be their scope of work. (VIDEO COMING SOON)

8th of December 2021

We are getting ready to start the engines.

For procedural reasons, prior to installing the engine / gear unit.

At the test stand, we start up and check the engines.

At the end of this stage, we will replace the filters and oil.

The next step will be to connect the motors with gears and prepare them for installation in the unit.

SHIPYARD LOCATION

Twarda 6A

80-871 Gdańsk

CONTACT

office@cormorantyachts.com

All rights reserved. © 2021, Cormorant Yachts

design: Hajduk Studio