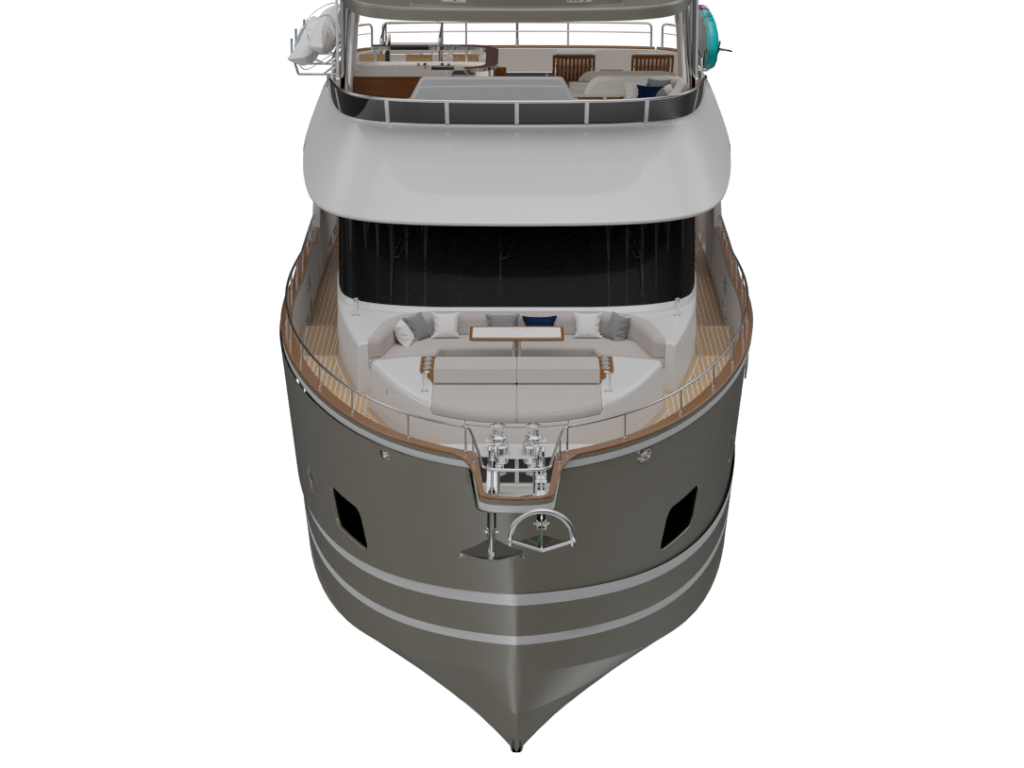

COR55/60 RAV It is an interesting alternative to traditional Trawler Yachts with a full raised Pilot House.

When designing this yacht, we tried to combine all the previously known solutions to create a nice and fresh silhouette.

Because COR55/60 is definitely a travel and family yacht. The design priority was broadly understood functionality. Decks, interior, mechanical, systems.

The hull of this yacht is a stable, semi-displacement shape. Provides excellent stability and efficiency at speeds of 7-10kts. At any time, allowing you to develop higher cruising speeds.

All systems and mechanical systems have been designed to be as simple as possible and easy to repair. components readily available around the world. Repair scopes can be easily performed directly by the owner-operator.

SEMI CUSTOM PRODUCTION.

The customer has a very large influence on the interior, finish, selection of systems, mechanical systems and tank capacity.

The construction program assumes that the ordering party will be involved in the construction process if he or she so desires.

The yacht is available in two general lengths: 55ft and 60ft.

It can be ordered without Flybridge. The scope of personalization is very wide and is limited to the hull geometry.

We have provided more information about the COR55/60 RAV in the Specification tabs.

| PROPERTIES | [m] | [ft] |

| LOA Length with short swimming platform 55/60 | 17,9/18.9 | 59 / 62 |

| BOA Beam overall | 5,425 | 17,79 |

| LWL Loaded waterline length 55/60 | 17,2/18,2 | 56.5/59,5 |

| T draft | 1,85 | 6.1 |

| DA draft air | 8,4 | 27,6 |

| D(T) Loaded displacment | 56,5 t | 100.060 lbs |

| CE APPROVAL CATEGORY | A Ocean | |

| Crew limit | 14 | |

| Hull type | Semi-displacment with ETE (Extended Trailing Edge) | |

| Hull Meterial | GRP | |

| Superstucuters / Deck | GRP | |

| Accomodation | 8+3 | |

| Sleeping places | up tp 11 | |

| Enigne Horse Power | form 2x230 up to 2x425 | |

| Speed | 5-15kts | |

| Averange range at 7kts | approx. up tp 4000 NM 15%reserv | |

| POSITION | NAME | |

| Naval architect | Grzegorz Władziński | |

| Analysis CFD and improv. | Grzegorz Władziński | |

| Conception designer | CY Damian Dymecki | |

| Exterior designer | Cormorant Yachts Team | |

| Interior designer | Cormorant Yachts Team | |

| Construction designer | STRUCTeam LTD UK | |

| Builder | Cormornat Yachts Shipyard Gdańsk | |

| PROPERTIES | [L] | [GAL] |

| Diesel total | 8700 | 2298 |

| Potable water tank | 400 | 92,47 |

| Fresh water tank | 1800 | 501 |

| Gray water tank | 600 | 158,52 |

| Black water tank | 600 | 158,52 |

All design attention was focused on travel and the yacht’s ease of maintenance.

A large number of storage compartments provide freedom to store everything you need during cruises.

The on-board equipment has been designed to be simple, effective and, when necessary, easy to repair.

The aftdeck with the right half-deck can be completely closed, and an additional hatch will isolate this space during a cruise in a cold climate and when the yacht is in port.

As has a huge FLY DECK with increased load-bearing capacity.

This provides the ability to load large dinghies.

The natural balance has been organized so that the weights on the FLYDECK do not change the trim of the yacht.

The stern platform can be made enlarged and can be lowered into the water.

In the COR60 RAV version, the Aftedck is large and allows you to accommodate a large table.

Thanks to the excellent experience of the Structeam design office from Great Britain, the structure was designed in a very thoughtful way. In addition to the massive and heavy hull structure, multi-point connection nodes were used.

The yacht is made of GRP.

The first 4 layers are made wet with vinylester resin, and fabrics and fiberglass mats are abundantly soaked.

The remaining layers are made using the polyester resin infusion method

The floor of the lower deck forms an intermediate structure together with the system of supporting frames.

The hull at the bottom is very heavy, which helps to lower the center of gravity.

All critical parts of the hull are made of SOLID.

The upper areas, such as the superstructure, are permanently laminated. However, their weight is lower.

Structural grid under the flydeck. Consisting of numerous connections, it is very extensive and provides very good support for future loads from the RIB, additional tanks and equipment located on the FLY DECK.

Hartop is a lightweight laminate construction.

We use the highest quality structural adhesives to connect the elements and laminate all connections with at least 4000GR.

We use components from companies for construction

AOC – Switzerland

BUFA – Germany

Scott Bader – UK

DIPEX/SAERTEX – glass fabrics

Glazing

CE compliant – A ocean + 20% surplus.

Pasted and grouted glass

Tempered laminated glass with a total thickness of 10 to 16 mm depending on the installation zone.

Storm-coated windows in steel frames are possible

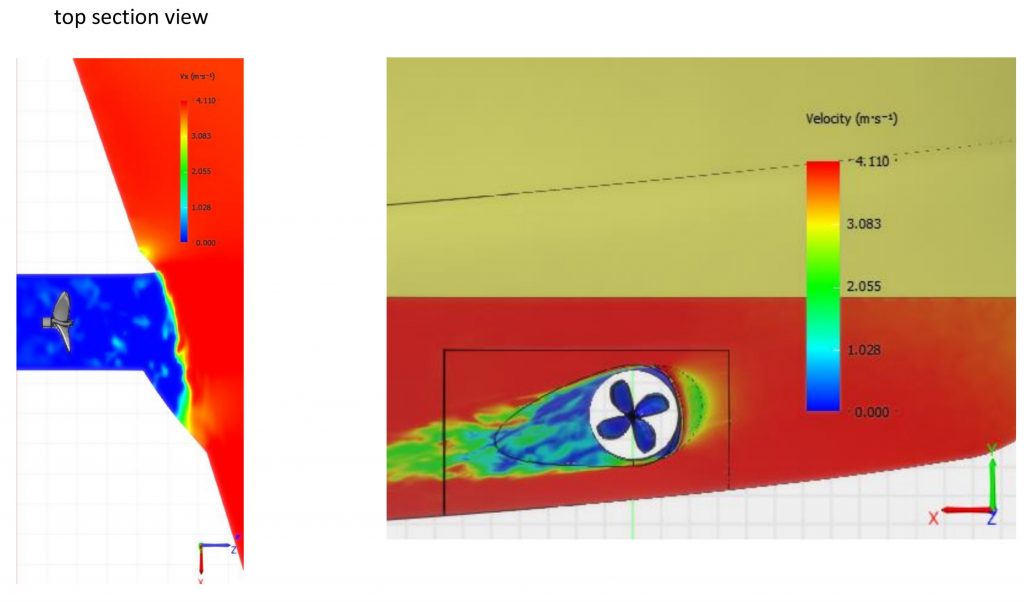

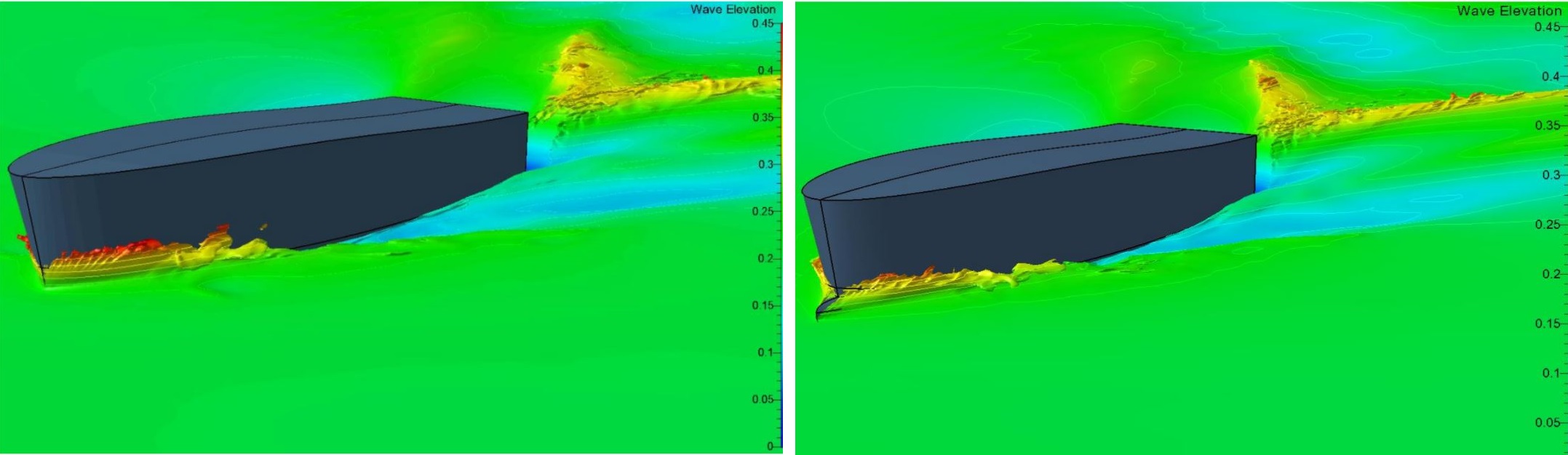

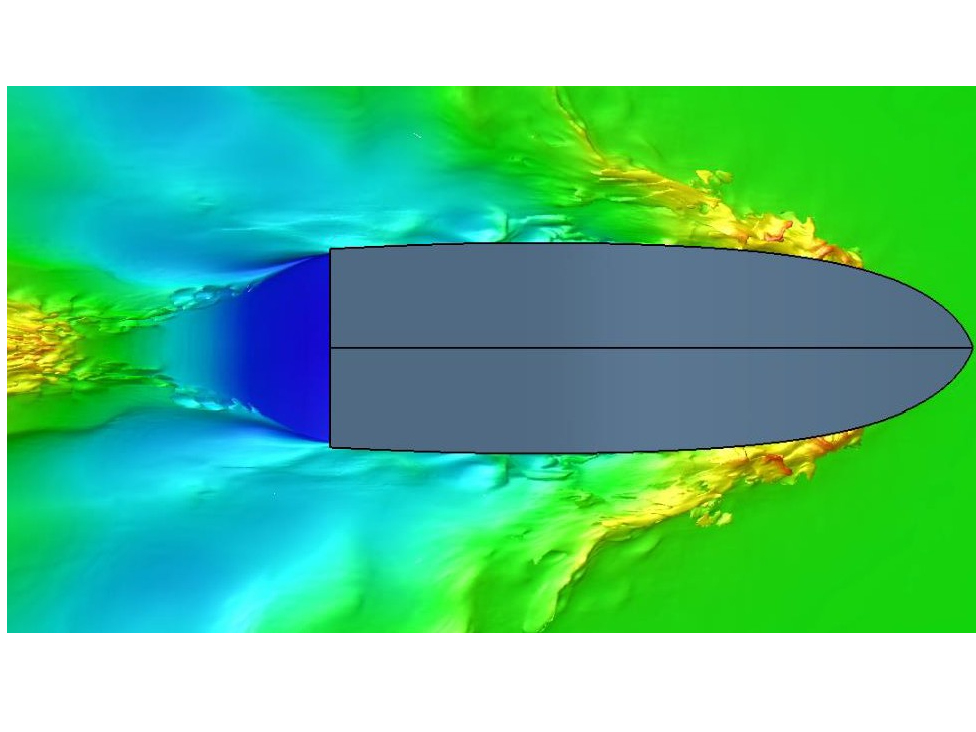

All the hulls we use have been designed directly for us by the office of engineer Grzegorz Władziński. In response to the high demands, hulls were created that combine the following features.

We do not use traditional pressure bulbous bows as they are only suitable for one speed. Instead, we use a more useful solution. Cutting bow that increases efficiency with speed.

In COR55/60 RAV Stabilization systems.

1.SLEIPNER Hydraulically driven 1.05sqm | 11.3sqft

2.SLEIPNER Electrically driven 1.1sqm | 11.8sqft

3.Passive anti-roll keels

In the case of a hydraulic system, it is combined with hydraulically driven thrusters.

There is no need to run the generator for the system to operate during the cruise.

Each CORMORANT has a hard-wire automation system. It is a panel with aesthetic buttons and controls. Its operation is the simplest possible. Starting a given system is done by pressing a button – and that’s it.

This solution allows the vast majority of devices to be connected with ordinary contactors. When the need arises, everyone will make repairs.

Moreover, for monitoring drive systems and generators. We assemble a Empirbus automation system. It is the highest possible quality electronic system made in Europe.

The system is expanded depending on the selected other equipment components.

The Empirbus system watches over all the yacht’s systems and displays them on its own screen or as a page on the MFD.

The levels in the tanks are also displayed in this system.

The system allows for enormous expansion possibilities according to customer wishes

Switch cabinets

First of all, it should be noted that regardless of the adopted configuration, solutions and materials are of the highest quality to ensure the highest level of safety and many years of trouble-free operation

ELECTRICAL SYSTEM

Each of the CORMORANTS 55/60RAV could be build with two different type of power systems. Depending on the needs and expectations of users.

LEVEL 1 – this is the range of devices without redundancy, corresponding to the coastal rib. Built on the basis of one KOHLER 12kW current generator. Large 6400W 24VDC / 230VAC Inverter and 500Ah Battery Bank common to all on-board devices.

One shore connection socket at the stern.

Starting aid for CYRIX engines / generators

LEVEL 2 – is a range of devices dedicated to units in the LRC configuration, and for those who expect higher comfort / security.

The scope has redundant systems. Split port and starboard layout. Switchable.

Two power generators (18kW large and 12kW small) associated for parallel operation, able to synchronize their work. This configuration allows the large generator to be turned off at night and only a small one will turn on when needed.

Two 6400W 24VDC / 230VAC inverters work in this system.

Two large 720Ah battery banks each

Two additional alternators mounted on 175A engines each

Two isolation transformers for shore power protection.

Starting aid for CYRIX engines / generators

Generators can be increased on customer’s request in each system.

You can change the type of batteries in each system. from AGM to LiFePO4 (Lithium Iron Phosphate Battery)

In each system, upon the customer’s request, other sockets, switches and power architecture can be used.

Each power supply system is easy to use and the switchboards are intuitive.

Each power supply system has a separate battery bank to maintain the radio function and a single plotter with a GPS antenna for several dozen hours in the event of a total failure.

This bank is located above the main deck.

Each CORMORANT 55/60RAV has six large earthing plates located in such a way that the loads are always discharged.

Basic navigation solutions are divided into two levels.

The basic system is GARMIN LEVEL 1

In addition to excellent shipyard and user support from GARMIN.

Upon special request, it is possible to install FURUNO systems

NAVIGATION LEVEL 1

MULTIFUNCTION DISPLAY & NAVIGATION

GPSMAP MFD 16″ 2pcs in the Pilot House

GPSMAP MFD 16″ 2pcs on the Fly bridge

GPS ANTENNA 24XD

PRIMARY AUTOPILOT REACTOR 40

SENSORS SAIL PACK 52 GNX (wind speed, wind direction, outside temp, water temp.)

RADAR GMR FANTOM 18

Communication:

Primary VHF – VHF 215i Pilot House + Full function handset on the Flybridge

NAVIGATION LEVEL 2

MULTIFUNCTION DISPLAY & NAVIGATION

GPSMAP MFD 22″ 3pcs in the Pilot House

GPSMAP MFD 16″ 2pcs in the Fly bridge

GPS ANTENNA 24XD

PRIMARY AUTOPILOT REACTOR 40

SENSORS SAIL PACK 52 GNX (wind speed, wind direction, outside temp, water temp.)

RADAR GMR FANTOM 18

RADAR GMR 1226 xHD2 open array antenna

CAMERA IP GC 200 in the engine Room

CAMERA IP GC 200 view stern direction

Communication:

LRC Transceiver package based on ICOM include:

Primary Radio Station VHF – Icom M605EURO Output Power: 1W/25W in the Pilot House + Flybridge stand alone panel

Secondary Radio Station VHF – Icom M605EURO Output Power: 1W/25W in the Pilot House + Flybridge stand alone panel

Icom M605Euro – Third stations Total Thee (3):

1.Engine Room Icom COMMANDMIC HM-229B + cables OPC-2384, 2.Crew Cabin, 3. Master Cabin

Radio Station HF/MF SSB – Icom M803 SSB Output Power:150W Frequencies 0.5-29.99Mhz

Radio Station SSB – The AT-140 automatic antenna tuner from ICOM M803 [is suitable for 1.6 to 30 MHz. Ideal for whip antennas, backstays etc. For 100 watts continuous power or 150 watts PEP]

Transponder AIS 800 TRANSCEIVER CLASS B

Antena GA™ 38 GPS/GLONASS

SATELLITE COMPASS MSC 10

inReach Mini Marine Bundle – Iridium satellite communicator

LEVEL 2 antennas package included:

One VHF Shakespeare 5230 Galaxy

One VHF Shakespeare 5309-R Galaxy VHF 23’ (7m) VHF Marine Band 9dB

One HF/MF Shakespeare 5310-R Galaxy SSB 23’ (7m) Full-Length Conductors

One AIS – Shakespeare 5225-XT-AIS Galaxy AIS/VHF Antenna 8′ (2.4m) 6dB Gain

One HDTV Shakespeare 3019 SeaWatch® Seawatch ® Marine TV Antenna (19″ Diameter)

One Shakespeare 5235-XT Galaxy AM/FM Antenna 8’ (2.4m) AM/FM Entertainment Band

One Shakespeare 5239 Galaxy 9.25″(0.23m) World Band Cellular Antenna

One Shakespeare – WiFi receiver in Marinas 5248 Galaxy Wi-Fi Antenna 24″(61cm) Gain:8dB

finished in superstructure colour

At the customer’s request, a second autopilot system with a KOBELT pump is installed

Thermal camera is also available on request in level 1.

There are a number of options for extending the navigation systems at the customer’s request.

All design attention was focused on travel and the yacht’s ease of maintenance.

A large number of storage compartments provide freedom to store everything you need during cruises.

The on-board equipment has been designed to be simple, effective and, when necessary, easy to repair.

The aftdeck with the right half-deck can be completely closed, and an additional hatch will isolate this space during a cruise in a cold climate and when the yacht is in port.

Jak has a huge FLY DECK with increased load-bearing capacity.

This provides the ability to load large dinghies.

The natural balance has been organized so that the weights on the FLYDECK do not change the trim of the yacht.

The stern platform can be made enlarged and can be lowered into the water.

In the COR60 RAV version, the Aftedck is large and allows you to accommodate a large table.

The COR55/60 RAV has a gravity fuel system with a day tank, fed from side tanks located in the Engine Room and tanks located in the bow/midship compartment.

Tank capacities according to customer specifications and needs.

The fuel system is equipped with a fuel distributor with a double fuel transfer pump, a fuel centrifugation and polishing system, and additional double filters for engines with a switching function.

The tanks have pollution traps and easily accessible drainage.

The day tank has space for sediment and water to accumulate, which does not provide fuel for engines and generators.

The tanks are made of 4 mm thick stainless steel, in accordance with ISO standards, with additional reinforcements.

Points outside the engine room are made of durable composites.

Tank filling points are located on the starboard side

Additionally, a fuel tank with a pump for refueling the dingy can be located on the FLY DECK.

Below we present charts based on which you can get an idea of the fuel consumption and range of the COR55/60. Please note that these values apply to yachts with standard equipment. additional tons in the form of optional equipment or the amount of fuel in additional tanks will affect the power requirement and, therefore, reduce the range.

First of all, it should be noted that regardless of the adopted configuration, solutions and materials are of the highest quality to ensure the highest level of safety and many years of trouble-free operation

See description in the SAFETY FIRST tab

COR55/60 It has a large space located right next to the keel for transporting media.

The configuration of fresh water, gray water, black water depends on the customer’s needs.

A typical configuration is:

Fresh water – 1800L

Gray water – 600L

Black water – 600L

The pipe installation is made of dedicated rubber hoses.

Anti-odor in black water installations.

Pressure installations are made in the VIEGA-Germany system

Fresh water distribution.

Gray water, toilets and waste water management

Emptying in the port. Could be pumping out the black water tank. While gray water is pumped into the black water tank. This solution helps to clean the black water tank. In addition, next to the sewage suction point, there is a rinsing valve, through which we can supply fresh port water, for cleaning the tank. The valves are located at the PilotHouse in degrees on the half deck starboard

Emptying in the sea. When the rules and common sense allow it. The gray water tanks are emptied directly into the sea using a sewage pump. The same has been solved for emptying black water.

DECK WASHING SYSTEM & ANCHOR WASHING SYSTEM

AIR CONDITION

EXTENSIVE HEATING SYSTEM

GENERAL VENTILATION SYSTEM

COR55/60 hull and propulsion

The hull has been designed so that the yacht is very effective in the range of 7-10kts.

Changing times and user trends have influenced the design of the hull, which has the ability to move faster. The most common reason is escaping to a port to escape bad weather and limiting time in open waters when traveling, e.g. between islands.

That’s why we give customers the opportunity to choose between several drive systems. The largest of them, 2x400Hp, allows you to achieve 14kts.

The drive configuration is a typical twin system.

It ensures quiet operation and excellent maneuverability.

This system is fully redundant.

To minimize maintenance needs, we recommend a keel cooling system and a dry exhaust system.

In this case, to reduce smoking when starting a cold engine. The engines are equipped with engine block heaters. This solution additionally reduces the wear of an underheated engine.

It is possible to order a yacht with one main engine located centrally and a wing engine with a lower power.

This solution will slightly lower operating costs.

The drive of a yacht sailing around the world must be easy to operate. Consumable parts are easily available and inexpensive. Widely available service and engines known everywhere.

Engines should meet exhaust emission standards around the world.

That’s why we chose JOHN DEERE engines and ZF transmissions.

We focus on two engine families

JOHN DEERE 6.8L and JOHN DEERE 9.0.

For installations with dry exhaust and keel cooling, these are models 6068AFM85 & 6090AFM85.

For installations with a wet exhaust system and heat exchanger, specifications with seawater subcooling of the charged air are possible. These will be the 6068SFM85 & 6090SFM85 models.

Each engine can be selected in the rating M1 to M4.

We recommend 230Hp for the 6.8L engine and 285Hp for the 9.0L engine. This will allow for greater system efficiency at speeds of 7-10kts.

The shaft line is angular with an inclination of 8°-10° and a four bladed propeller with a diameter of 40″

ZF 85A series gears, gear ratio i=2.5

propeller rotation speed at 7kts.

6068AFM85 M1 230HP = 480RPM

6090AFM85 M1 285HP = 400RPM

ZF 301-1A series gears, gear ratio i=2.9

propeller rotation speed at 7kts.

6068AFM85 M1 230HP = 413RPM

6090AFM85 M1 285HP = 344RPM

SHIPYARD LOCATION

Twarda 6A

80-871 Gdańsk

CONTACT

office@cormorantyachts.com

All rights reserved. © 2021, Cormorant Yachts

design: Hajduk Studio